A la hora de diseñar un packaging hay tres pilares fundamentales:

Guideline donde se describen las reglas corporativas respecto, colores, proporciones, posición de elementos y logos, en definitiva la esencia de nuestra organización.

Los textos a implementar, generalmente un documento word idílicamente revisado por el departamentos de asuntos regulatorios o marketing según el tipo de producto.

El documento técnico aportado por el fabricante o impresor donde se definen las medidas, tipo de material, grosor y reglas en códigos visuales.

Centrándonos en el documento técnico, en primera instancia no debería ser un problema dado que el impresor, debería aportar un documento con sus reglas para que el diseñador implemente los textos necesarios con la esencia del cliente.

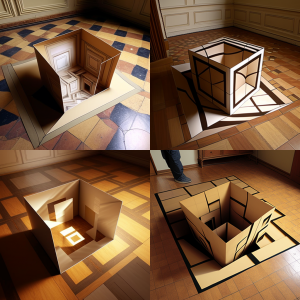

Cuando me preguntan que hago en mi trabajo me gusta decir que hago puzzles, y para ello las piezas deben encajar, ¿verdad?.

Cómo debe ser un documento técnico

Los detalles en estos documentos son esenciales para garantizar que el diseño y la producción del envase se realicen de manera eficiente y efectiva. Después de más de 20 años produciendo packaging con miles de modelos el proceso se puede hacer tan complicado como poco claro sean sus reglas además de las muy comunes omisiones de información por lo que básicamente debe incluir solamente cinco detalles bien definidos, sólo cinco:

1.- Escala 1:1, es decir, una escala correcta sin proporciones incoherentes. Del mismo modo ya se ven poco, pero no hace mucho podías encontrar planos hechos con el famoso Autocad con diseños mal escalados e inservibles para su uso y edición en herramientas básicas de diseño como Illustrator o Indesign.

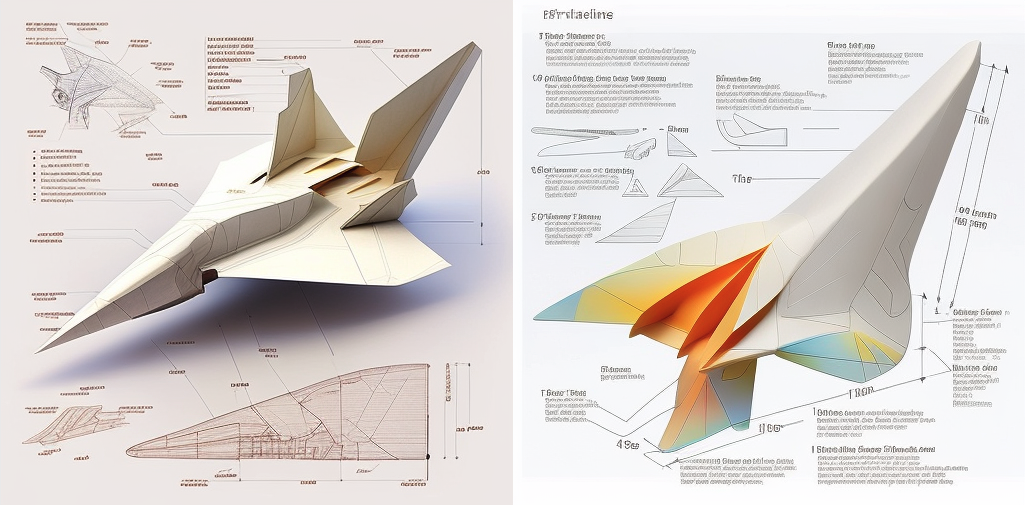

2.- Especificaciones respecto al material, incluyendo gramaje, grosor, si es un material reciclado y siendo exquisito una ayuda visual para sabes si es un papel continuo en rollo o si es tipo cliché entre.

3.- Límites y máximos, donde debe especificarse detalles como los márgenes, zonas de impresión o por el contrario zonas libres de texto donde no debemos incluir información dado que dicha zona tiene una reserva para incluir los datos variables o es una zona de plegado, por ejemplo. Otros detalles serían la posición del braille, localización de las etiquetas para garantizar la inviolabilidad, los datos variables como loteado o fecha de caducidad y posición de los datos de la famosa serialización.

4.- Reglas respecto a los códigos visuales, en éste apartado hay mucha variedad como laetus, códigos 128, datamatrix, collating marks (perdón, no conozco la acepción en español). En cualquier caso todos estarán bien definidos si se define: posición, orientación, dimensión y color.

5.- Colores, definiendo aspectos como el máximo de colores posibles, especificar si debe tener un color específico como negro muy común en un prospecto. La excelencia en éste apartado sería tener una nomenclatura de los colores técnicos, es decir, lo contrario a recibir un documento en cuatricomía (CMYK). ¿Es mucho pedir un documento con colores bien estructurados?. Si recibes de tu impresor un documento técnico con colores con una nomenclatura como la siguiente: dimensions, cutting, creasing, guides, perforating, Text Area, Text Free, Ink Free, solo me queda aconsejarte que felicites a tu impresor y que sigas trabajando con él todo lo que puedas.

Para terminar, exige a tu impresor que cumpla con éstas cinco pautas, la excelencia esta en la búsqueda de la mejora continua, de ésta manera te vas a ahorrar mucha frustración cuando te llegan una y otra vez rechazos de tus materiales incurriendo en versiones innecesarias y los nunca deseados retrasos sin mencionar la gran importancia si hablamos de nuevos lanzamientos.